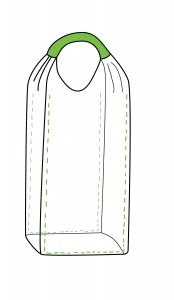

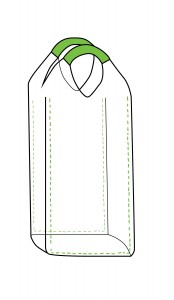

The 1- Loop and 2- loop bags are cost effective and suitable for bulk handling solutions. These bags are mainly used for storing larger volume and high capacity contents like, fertilizers, fish-feed, cement, seeds, chemicals, minerals, food grains, etc. These bags are available in both inner liner and outer liner options. Apart from options these bags can be produced with filing and discharge spout, suspended liner, multi-trip, UN approved for hazardous goods, etc.

Benefits

- These bags are cost-effective

- Best in handling with their qualities

- Easy to fill, discharge and store

- Easily transportable

Details About 1 & 2 Loop Bags.

Body Construction : tubular fabric no vertical seam available with different types of fabric weight/colours

Fabric : PP with High tensile strength and UV stabilized

Minimum 50x50cms width

SWL : 500Kg -2000 Kg

SF : 5:1 & 6:1

Lifting : one point or two point

Top : Open or Spouted.

Bottom : Flat base, Double Layer, Star Bottom, Square base, Base with discharge spout, folded bottom

Printing : 4 color per side, maximum up-to 6 colors per side with double round.

Liner : Coextruded LDPE / LLDPE liner (30 to 150 µm)

Shapes of liner : Bottle neck, tube form, form shaped , suspended, Shoulders sealed with vent holes, Gusseted liners, Glued liners, liners folded over loops, liners with Different dart impact strengths possible, can be Transparent or colored liner, also available with Different levels of permeability

There is a direct relation between the inner bag and bagging speed. Upon request the inner liner can be pre-blown and shaped, which results in significant improvements in bagging speed.

Types of Bag : UN Bags , Food approved Bags , industrial clean bags.