UN bags are special type of FIBCs are designed to comply with the United nations Recommendations on the Transport of dangerous Goods, known as the “Orange Book”. These FIBCs are used for transportation of dangerous Goods like chemicals fertilizers and compounds. The UN bags are designed and tested in accordance with the recommendations laid down in the “United Nations Recommendation on the Transportation of Dangerous Goods.

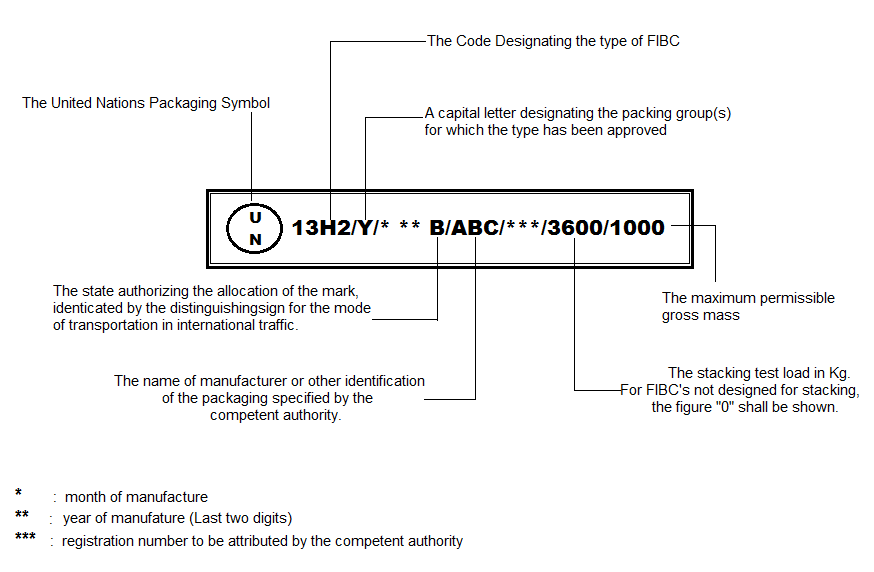

“Orange Book” had classified IBC into 6 categories, which included 4 types of FIBC as follow:-

- 13H1 – PP woven FIBCs, without coating.

- 13H2 – PP woven FIBCs, coated.

- 13H3 – PP woven FIBCs, with liner, without coating

- 13H4 – PP woven FIBCs, with liner and coating

A UN FIBC is subjected to the following tests:

Top lift test

The FIBC is loaded with six times the maximum load.

Drop test

Depending on the packaging group, the FIBC filled with the maximum load is dropped in an upright position from a height of 80 cm or 120 cm.

Topple test

Depending on the packaging group, the FIBC filled with the maximum load is toppled from a height of 80 cm or 120 cm.

Righting test

After being toppled, the FIBC filled with the maximum load is lifted to an upright position on one or two loops.

Tear test

A 100 mm tear is made on one of the sides of the FIBC filled with the maximum load. The FIBC is then filled with twice its maximum load for a minimum of five minutes. Finally, the FIBC is suspended with its SWL for another five minutes.

Stacking test

The FIBC filled with the maximum load is loaded with 1.8 times the weight that is permitted on top of the FIBC.

It can be produced with options like;

- Coating

- Colour

- Printed

- Dust proof

- With Liner

- And various inlet and outlet closures